Charcoal making is an ancient art dating from 6000-8000 BCE.

Charcoal making is an ancient art dating from 6000-8000 BCE.

In a carefully controlled process known as pyrolysis, all moisture and most of the volatile materials contained in wood are removed, leaving almost pure carbon. The resultant charcoal burns at 600 to 1200 degrees Celsius, producing an even, smokeless heat.

Preparation

To prepare the kiln on this site for firing, a crib floor was laid over cedar logs set lengthwise above a subfloor,with channels for the air to flow from the entrance to the flues. On top of the crib was packed a floor of sand and dirt.

Loading

20cm diameter logs of alder (sometimes fir or maple) were stacked vertically side by side, reducing in diameter toward the front opening.

Capping

Once the kiln was filled, a thick layer of sticks and branches were placed over the logs. These were covered using a sand-clay-soil mixture, packed firmly to make a dome of 20cm thick.

Protection

The kiln would also have had a framed roof to protect the firing process from rain, as charcoal making was mostly done in autumn

Air Flow

This pit kiln has a typical teardrop design, dug out of the slope and forming an earthen mound lined with stone. Two flues are built half-way up into the walls and a metre away on each side of a central outlet chimney; all help regulate the flow of air, and control the heat.

Insulation and Drainage

15cm below the floor, a hidden subfloor of split cedar logs was laid across the width of the pit. This subfloor had two purposes: to act as an insulator for the ground heat, and to drain moisture and volatile acids toward the central chimney in order to be burned out.

The Process

The charcoal maker would light the fire at the narrow front opening, and then give his full attention to the burning. At the beginning white smoke would pour out the flues and it would take the day to get the kiln going.

A large tub of water would have been kept nearby in the event that a fire broke through the dome. If it did,water and more sand-clay mixture would be used to repair the leak. As the temperature in the kiln rose, moisture and volatile acids would be released from the logs, and the entrance way would be closed except for a small air intake.

The charcoal maker would judge the conditions in the kiln by observing the four stages of carbonization, revealed by the colour of the gases coming out the flues: white, yellow-white, blue and finally translucent. A slight odour of alder wood – not smoke – would be the sign to end the smoldering by covering the air intake and the three flues.

With all oxygen cut off to the kiln, carbonization would be complete. After one or two days’ wait to make sure the fire was out, the kiln was ready to be opened. The charcoal would then be removed, packed into rice sacks for market and taken down the hill to be loaded onto boats in Active Pass.

A century later, charcoal is still widely used, for barbecues, filtration, odour removal, art materials, smelting, soil enhancement and even as an ingredient in cosmetic products.

Volunteers Needed!!! There will be a work party on Saturday, October 26 to relocate the Shorepine trail in the Community Forest. We will also be doing some trail maintenance on that trail. Please join us if you can.

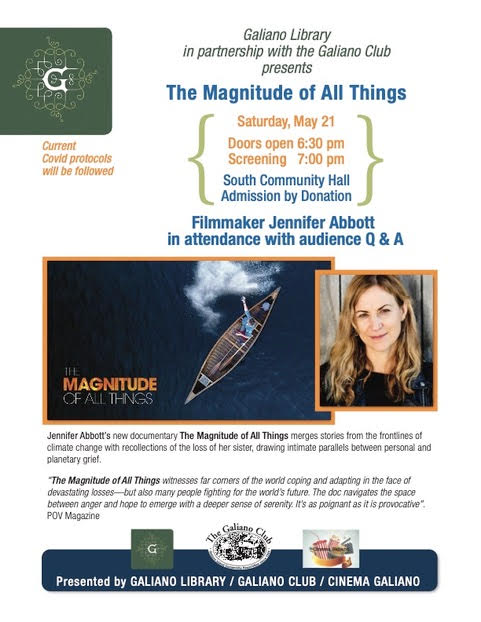

Volunteers Needed!!! There will be a work party on Saturday, October 26 to relocate the Shorepine trail in the Community Forest. We will also be doing some trail maintenance on that trail. Please join us if you can. Coming Friday Sept 13th and Saturday September 14th!!! Come be impressed by your incredibly talented (or un-selfconscious) island neighbours.

Coming Friday Sept 13th and Saturday September 14th!!! Come be impressed by your incredibly talented (or un-selfconscious) island neighbours. Charcoal making is an ancient art dating from 6000-8000 BCE.

Charcoal making is an ancient art dating from 6000-8000 BCE.